MS 3000

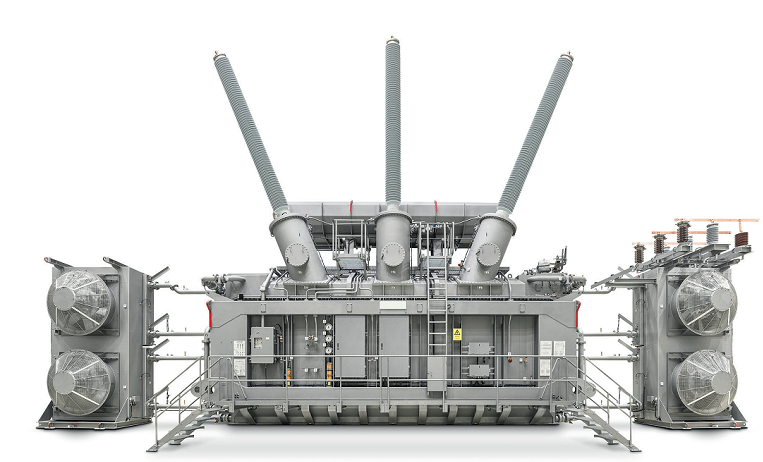

Faced with increasing pressure to continuously improve network availability and reliability, asset owners are now often looking for increased coverage on their important transformers. Continuously monitoring the transformer’s main components (active part, bushings, and tap changer, cooling system) is a key to maximizing transformer availability, reliability and performance while reducing the life-cycle cost. Asset owners are therefore expanding beyond Dissolved Gas Analysis (DGA) and connecting to or adding more sensors to extend their online monitoring reach.

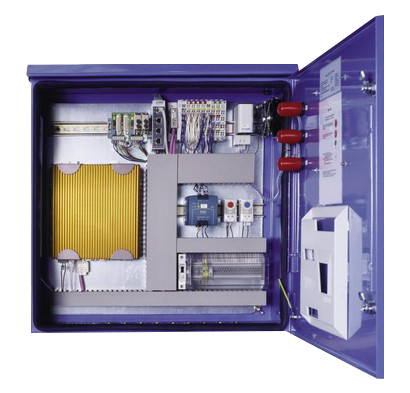

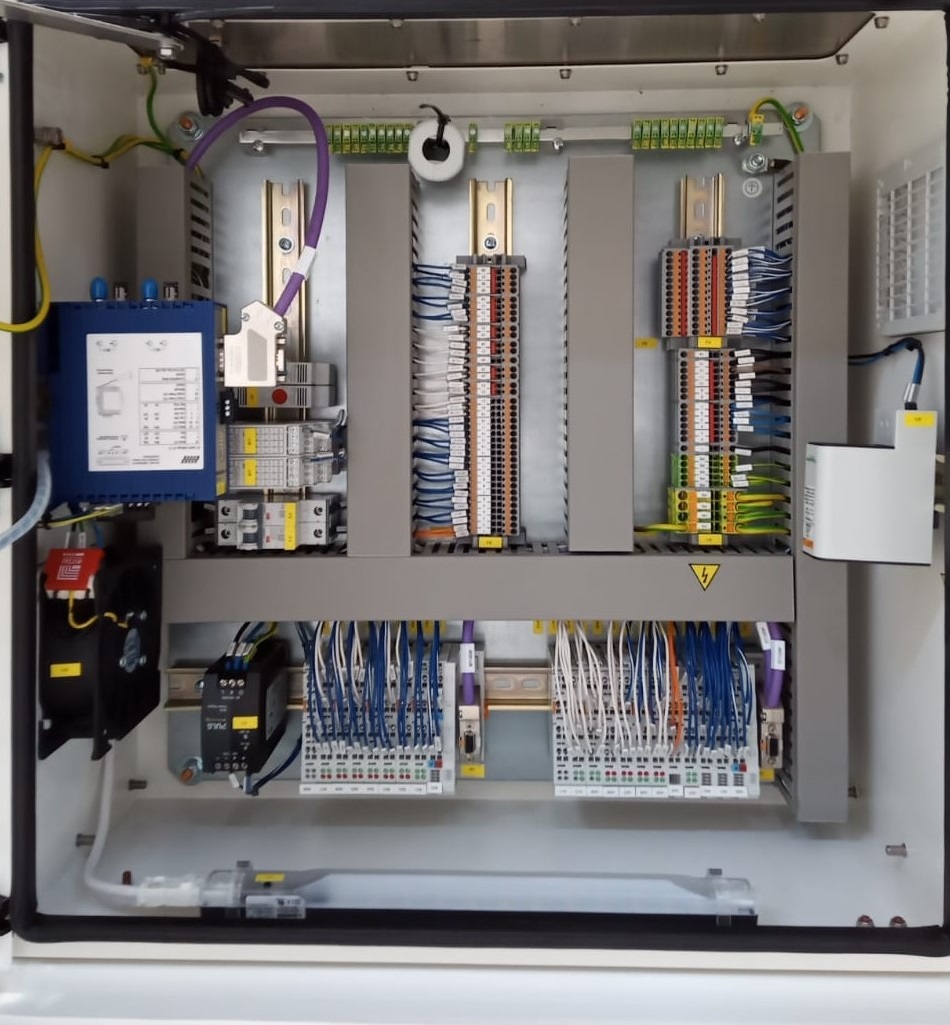

GE’s MS 3000 holistic and modular transformer monitoring system enables essential to comprehensive coverage of the most common causes of failure. It lets you combine the outputs of available sensors to form a homogeneous data flow coming from a single source. It uses analysis and sophisticated models to prevent data overload and deliver an aggregate view of the health of the transformer’s main components, providing intelligent alarms, diagnostics and suggested operational next steps. The MS 3000 is an “Expert System” which helps you confidently assess a transformer’s condition and optimize its operation and maintenance.

Key Benefits

- Continuous supervision of the whole transformer, integrating data from available sensors

- Modular: essential through to comprehensive coverage of transformer failure modes

- Optimum operation efficiency with reduced life-cycle cost

- An “Expert System” to help you assess and manage your costly assets

- Modular: essential through to comprehensive coverage of transformer failure modes

- Web server HMI, no need for software to access the data analysis

- Integration with GE’s Perception software for centralized information and leveraging of fleet data

- Easy inter-operability of the transformer with the Smart Grid / Digital Substation

A MODULAR AND FLEXIBLE SOLUTION COVERING THE KEY TRANSFORMER ELEMENTS

A modular and configurable system that can monitor the various key components of a power transformer listed here, depending on the asset owner’s requirements.

Expert System

Algorithms for analysing the data acquired online are implemented in the software and reflect GE’s extensive experience with transformers. The expert system highlights issues through configurable alarms and provides clear correlated information as well as recommendations concerning the transformer continued operation, the suggested “next steps” and the need for services and maintenance

- Load currents (A)

• Over-currents (A)

• Total number of over-currents (A)

• Load factor (A)

• Overload capacity (A)

• Emergency overloading time (A)

• Apparent power (A)

• Active power

• Reactive power

• Transformer power factor (cos φ)

• Transformer losses

• Bottom oil temperature

• Calculated hot spot temperature (A)

• Winding temperature

• Moisture in insulation paper (A)

• Bubbling temperature (A)

• Bubbling safety margin (A)

• Gas in oil rate of change (A)

• Moisture in oil content (A)

• DGA in OLTC

• Transient lightening over-voltages (C).

• Total number of over-voltages (C).

• Change of C1 capacitance (C).

• Power factor (tan δ).

• Oil/SF6 pressure/density.

• Capture of full waveform.

• UHF PD.

• Number of switching operations (A)

• Number of operations until service (A)

• Cum. switched load current (A)

• Cum. current until service (A)

• Power consumption of motor drive (B)

• Motor drive current

• Operation timing (B)

• Assessed mechanical condition (B)

• Energy index (B)

• Contact erosion

• Gas in oil content

• Moisture in oil content

• Oil temperature

• Oil temperature differences

• Oil level in OLTC

• Ambient humidity.

• Cabinet temperature.

• Oil pressure.

• Humidity of air inside conservator.

• Gas quantity/gradient in Buchholz relay.

• Other digital and analogue inputs.

• Other parameters on request.

Both off-line and online data can be analysed. DGA using the most common diagnostic tools: Duval’s triangle, Rogers and Doernenburg ratios, Key Gas methods, etc… as per IEEE C57.104 and IEC 60599. Users can select the method most appropriate to their situation. They can also perform Furfural determination and oil condition evaluation according to IEC 60422

The built-in simulator module allows the user to simulate external events or internal transformer events and to study the corresponding effect on the transformer’s behaviour. It can be invaluable for weighing up options when faced with a difficult decision but can also be used for training of personnel.

The configurable report generator quickly and easily creates a user-friendly report onthe status of the transformer and of its main components. The report can be created on demand for selected monitored functions over a specified time frame.

The Web server built into the MS 3000 provides web pages in several languages which can be accessed using a standard web browser. The key data overview screen will highlight any alarm and enable to drill down into more specific data. When part of a transformer fleet, integration with GE’s Perception software** enables centralized information, leveraging of fleet data and fleet health ranking.

With a multitude of sensors constantly delivering refreshed online data, the MS 3000 uses sophisticated models to analyse all this data, correlate it when additional sources are available and convert the data into actionable information in order to enable the asset owner to get the most out of the transformer.