- Home

- S&C Electric Product

- Omni-Rupter® Switches

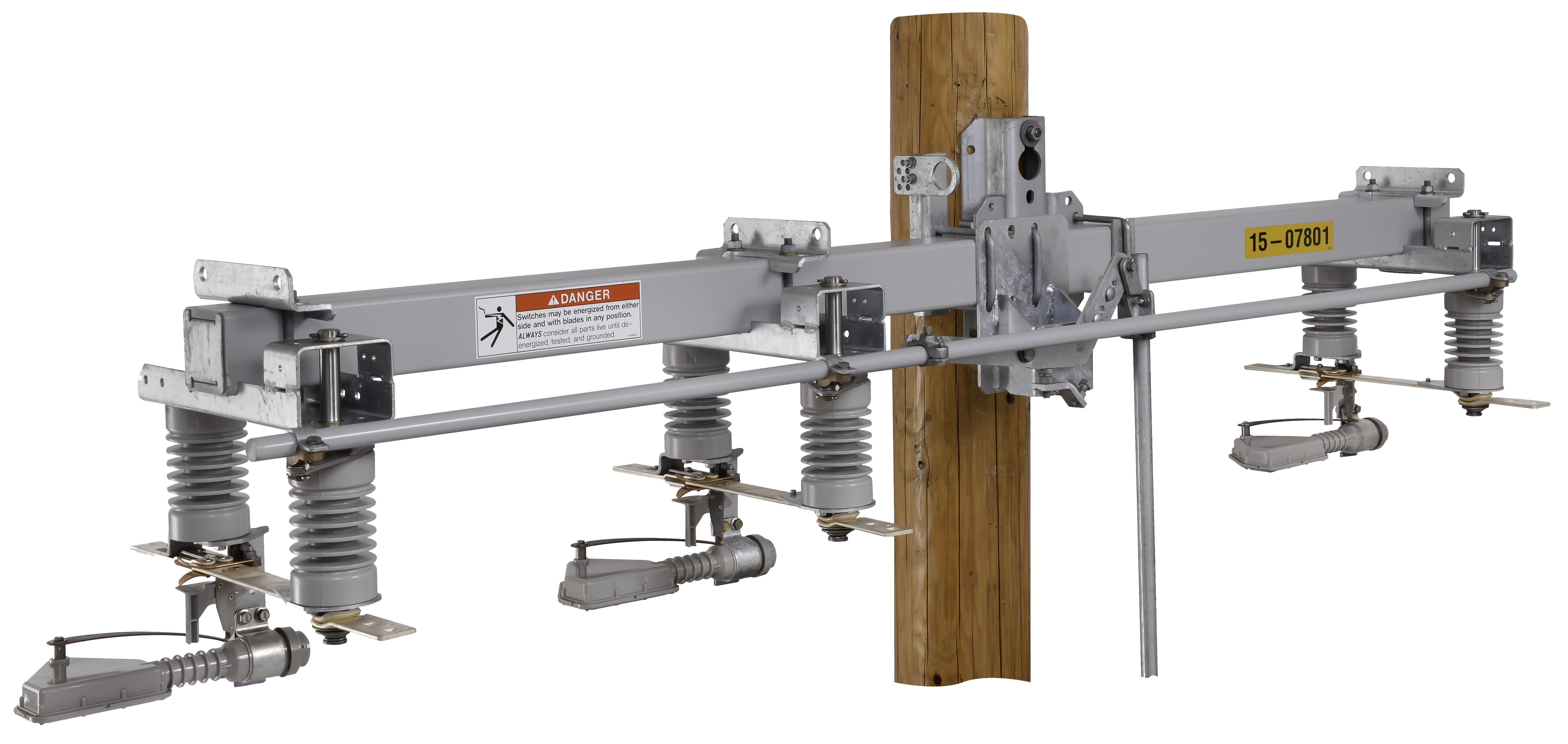

Omni-Rupter® Switches

For outdoor distribution, 14.4 kV through 34.5 kV

S&C Omni-Rupter Switches are load interrupter switches expressly designed to handle the switching duties on today’s overhead distribution feeders. Omni-Rupter Switches provide long-life, high-performance, no-external-arc circuit interruption, and they are ideally suited for the following switching duties:

- Line switching, including sectionalizing and feeder switching

- Transformer switching

- Cable switching

Omni-Rupter Switches are rated 900 amperes continuous and interrupting in voltage ratings of 14.4 kV and 25 kV, and rated 630 amperes continuous and interrupting at 34.5 kV. These gang-operated interrupter switches are available in a number of mounting configurations to accommodate a wide variety of line configurations encountered on today’s distribution systems.

S&C Omni-Rupter Switches meet all three criteria for a well-designed interrupter switch:

- Dependable Operation

Omni-Rupter Switches are designed to be maintenance-free under normal operating conditions, and they only require periodic inspection following utilities’ standard inspection schedules for pole-mounted distribution equipment. The interrupter shunt arm and the auxiliary return arm on the blade cam work together to ensure the interrupter is closed when the switch is closed, and they are ready to interrupt current when called upon. All Omni-Rupter Switches come factory-aligned for three-phase simultaneity with no field adjustment. This ensures they will remain three-phase switches—on day one and years down the road.

- Simple Installation

Integer-style Omni-Rupter Switches ship factory-assembled on a single-base for easy-up installation. The single-point lifting bracket provides a simple means to lift the switch into position, and the bracket stays on the switch without interfering with built-in dielectric clearances.

- Robust Capabilities

Omni-Rupter Switches are capable of interrupting up to 900 A through 29 kV and 630 A through 38 kV, and are rated for switching duties including load-dropping, loop splitting, and line- and cable-charging. Spring-driven interrupters provide a consistent interrupting speed, ensuring full interrupting capability regardless of the speed of operation. Field-replaceable sacrificial guide fingers serve as fault-closing contacts and ensure the main current carrying contacts and interrupter are protected—enabling substantial two-time and ten-time fault-closing capabilities.

- Multi-purpose operating cams ensure consistent current transfer into the interrupters for no-external-arc switching. The auxiliary return arm provides added assurance the interrupters are closed when the switch is closed, eliminating the possibility to get out of sequence.

- Single-piece blade is made of nickel-silver-plated copper and is aligned at the factory without any requirement for field adjustment. The copper-tungsten arcing tip embedded in the blade provides resiliency to withstand fault-closing operations.

- Single-piece base is factory-assembled and adjusted for three-phase simultaneity and easy-up installation.

- Unique clamping system securely and permanently locks pole-units to the base, ensuring three-phase simultaneity with no need for adjustment.

Galvanized steel pole-mounting bracket accommodates steel or wood poles from 5½ inches (140 mm) to 14 inches (356 mm) in diameter to suit a wide variety of installations

Application

Designed to Handle Distribution Feeder Switching Duties

Omni-Rupter Switches are rated 900 amperes continuous in voltage ratings through 29 kV, and 630 amperes continuous in voltage ratings through 38 kV. Arc extinction takes place within the interrupters, which use a specially designed trailer and liner to create the necessary gasses for efficient circuit interruption. The latch-and-spring mechanism inside the interrupter provides a consistent speed of interruption, guaranteeing full interrupting capability regardless of the speed of operation. These interrupters help make OmniRupter Switches ideally suited for:

- Line switching—Load splitting (parallel or loop switching), load dropping, and associated charging currents

- Transformer switching—Load dropping, including associated magnetizing currents

- Cable switching—Load splitting (parallel or loop switching), load dropping, and associate charging currents

Omni-Rupter Switches provide dependable operation even in areas subject to icy weather conditions. Mechanical and electrical switch operation is ensured even under an ice buildup of up to ¾-inch (19 mm), depending on the mounting configuration.