- Home

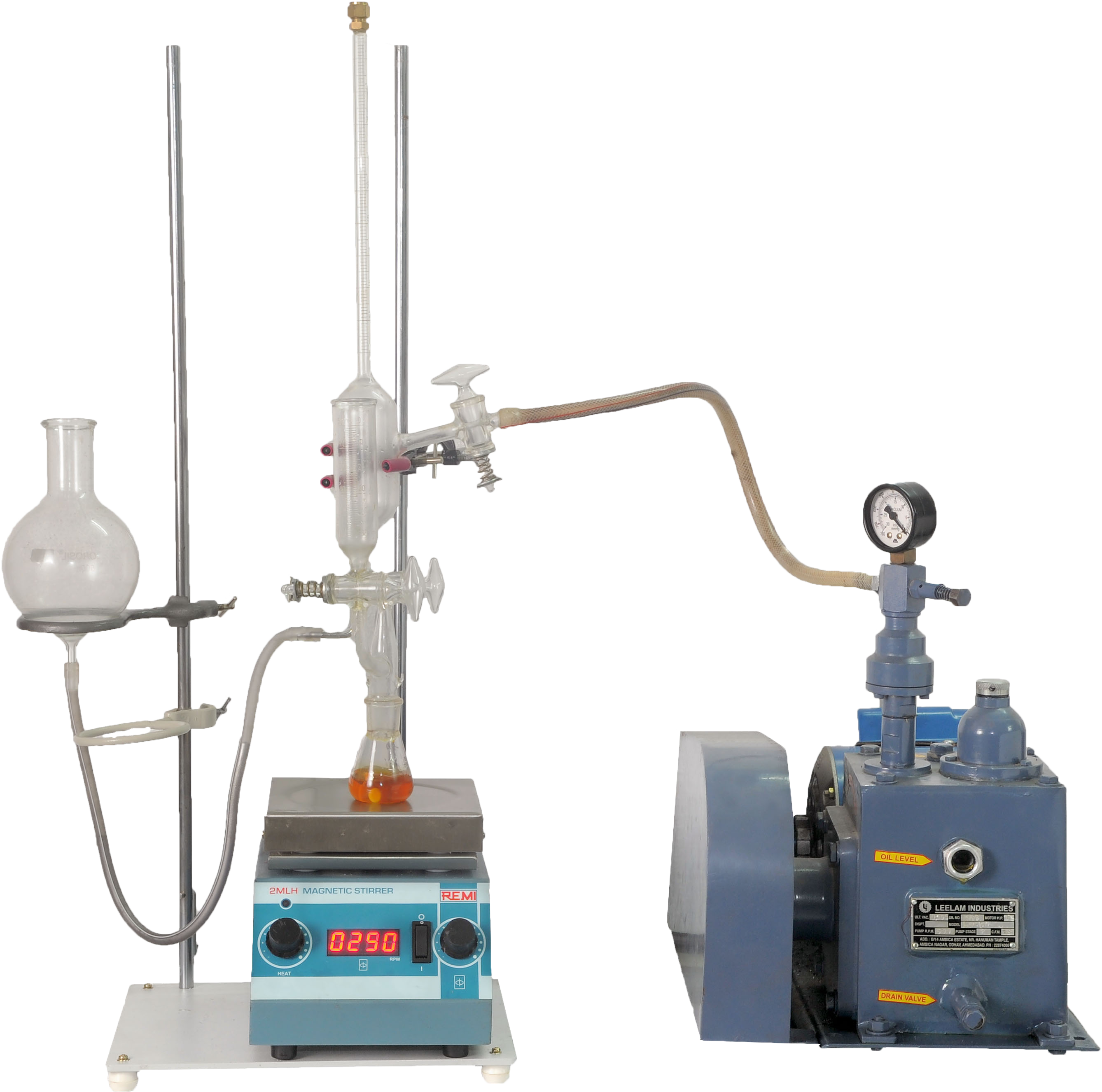

- Laboratory DGA

- TOGA Analyzer Model 2010 with PDG

TOGA Analyzer Model 2010 with PDG

Our Analyzer Model 2010 can be used as per ASTM D 3612, Section A / C or IEC 60567, 2005 Section 7.3 / 7.5 or IS 10593 / IS 9434. This equipment can be used to detect the incipient fault in the Power Transformers, Reactors, Electric Loco’s, EMU trains, Metro Trains etc and arrest deterioration/damage to the transformer insulation by analyzing gases dissolved in the transformer oil and adopt preventive measures.

Gas Chromatograph method is used for detection for the dissolved gases and identification of incipient faults. The most significant gases generated by decomposition of oil deterioration, of paper insulation on the conductor are Hydrogen, methane, ethane, ethylene, acetylene and carbon di-oxide. The quantities of these gases dissolved in transformer oil vary depending upon the type and severity of fault condition such as arching, partial discharge, overheating, low-high temperature hot spot etc.The process involved is separation, identification and quantitative determination of gases.

The Gas Chromatograph will be calibrated by injecting known amount of pure gases, and after that extracted gases of known sample will be injected in gas chromatograph for Separation and analysis. Our Gas Chromatograph will determine Hydrogen, Nitrogen, Oxygen, methane, ethane, ethylene, acetylene (C2H2), Carbon mono oxide and carbon di-oxide.

Features

- Micro convector based 24-bit controller super digital temperature controller / programmer with control of 6 heated zones (4 standard & 2 optional).

- 24-bit micro convector based.

- Up to 128 KB of storage inbuilt in processor.

- ±10C control.

- 99 Steps Programming.

- Up to 99 Method Files Storage.

- 32 Key Membrane Keypad with Large LCD Display of 20 characters X 4 Lines

- User settable alarm set points.

- User settable safety cutout for overall system.

- Auto cooling set point through keyboard.

- Self-Diagnostics and fault diagnosis in front panel display.

- Besides the above system also has green colour LED’s for each zone for heating and RED colour LED for alarm indication. Separate LED’s are also provided to display the programming option.

- The controller also has a start key which gives pulse for the Data Acquisition System to start acquisition.

- The controller also has individual heating on and heating off keys with self-indication to individually heat the different zones.

- Six independent heating zones.

- Trouble shooting chart is provided in the manual for action to be taken for the repair of the equipment corresponding to each error.

- Separate keys for all heated zones are provided and when pressed they show the temperature profile of that zone. This key can be pressed and feature accessed from any screen of the software.

- Continuous and simultaneous display of 6 heated zones with Actual temperature and set point as default Main screen.

- Alarm screen appears until acknowledged and alarm LED remains glowing till the time alarm / fault is rectified and is recorded in the Non- Volatile Memory of the system.

- Buzzer for all keys is provided which indicates the pressing of any key.

- All alarm conditions are also indicated by a buzzer signal till the time it is disabled.

- Different keys are provided for scrolling of pages as well for scrolling of sub menus within the main menu.

Dissolved gas interpretation software and diagnosis of faultssoftware

- Special DG Interpretation software for computation and interpretation of the results of analysis of dissolved gases in transformer oil. Our programs start from the ppm level of detection of C2, H2, CH4, C2H4, H2 and C2H6. Software having the following facilities –

- It will compute results in ppm by comparing calibration standard and give you ppm level of C2H2, C2H4, CH4, H2 and C2H6.

- It will use the calculation form as per IS 10593 and compute the ppm level of dissolved gas in transformer oil. This will give your figure of all dissolved gases in ppm level.

C2H2 CH4 C2H4

——– ——- ——–

C2H4 H2 C2H6

- Also this will give print out additional table of permissible concentration of dissolved gases, which will give you the idea of condition of the transformer. Based on above transformer and will indicate about the type of fault in your transformer.

The software will also display the faults associated with presence of more than permissible levels of different gasses in oil.

Touch Screen GC System Model DHRUVA S2TS has various applications in the field of Power Generation Sector, Transmission Sector, Railway Sector, Transformer Manufacturers, Distribution Companies, Oil Testing Laboratories, Electrical Testing Laboratories, Transformer Monitoring Mobile Van, GIS Substation, Refineries and Petrochemical Sector