- Home

- Inorganic Elemental Analyzer

- Oxygen-Nitrogen Analyzer

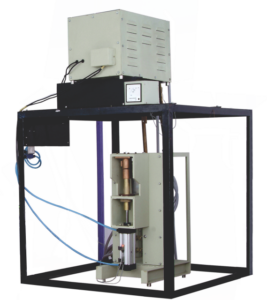

Oxygen-Nitrogen Analyzer

The Oxygen – Nitrogen analyzer is capable of Oxygen& Nitrogen determination with great simplicity using latest technology and menu driven software. The operation of the analyzer is simplified with the use of Touch Screen based control systems which make the dual Detectors for the ON analysis – A very high sensitivity Macro Thermal Conductivity Detector & Micro Non Dispersive Infra-Red Detector capable to detect from low to high ppm using a nominal sample size.

Key Features

- • Compact and Modular design for ease in operation &maintenance

- • It has a large ¼” VGA Touch Screen for the complete control of the system. There is no keypad or other controls visible on the front panel as the complete operation is through the touch screen panel including / excluding current setting for out gas and analyze mode. The complete system is under mod bus RTU protocol for connectivity through other SCADA & supervisory systems

- • Data acquisition is through software using a PC system so that unlimited files can be stored

- • All the timers are user settable (via Supervisory password) thereby making the instrument ideal for routine analysis as well as R & D application. The timers for all the modes are set using the touch screen as well as through the Determinator control software

- • On line display of the current mode in progress as well as the time left for mode completion displayed on the touch screen

- • On line fault diagnosis and stepwise guidance for any fault condition on the Touch Screen console

- • On line Manual, On Line Method Development and On Line Fault Diagnosis software in case the Determinator control software is procured

- • Three stage flow control system to prevent accidental change of values

- • Alarms and safety interlocks

- • Closed loop coolant circulatory (Optional)

- • Furnace is Glove Box adaptable(Optional)

- Compact and Modular design for ease in operation &maintenance

- It has a large ¼” VGA Touch Screen for the complete control of the system. There is no keypad or other controls visible on the front panel as the complete operation is through the touch screen panel including / excluding current setting for out gas and analyze mode. The complete system is under mod bus RTU protocol for connectivity through other SCADA & supervisory systems

- Data acquisition is through software using a PC system so that unlimited files can be stored

- All the timers are user settable (via Supervisory password) thereby making the instrument ideal for routine analysis as well as R & D application. The timers for all the modes are set using the touch screen as well as through the Determinator control software

- On line display of the current mode in progress as well as the time left for mode completion displayed on the touch screen

- On line fault diagnosis and stepwise guidance for any fault condition on the Touch Screen console

- On line Manual, On Line Method Development and On Line Fault Diagnosis software in case the Determinator control software is procured

- Three stage flow control system to prevent accidental change of values

- Closed loop coolant circulatory (Optional)

- Furnace is Glove Box adaptable(Optional)

Application

Oxygen – Nitrogen Analyzers are widely used for analysis of Oxygen and Nitrogen which are applicable for many purposes like:

• Refractory Metals (Ti, Zr)

• Ceramics

• Super Conductors

• Rare Earths

• UO2 / MOX

• Steels and Ferro Alloys

• Aluminium and Al Alloys

• Copper and Copper Alloys

• Nickel and Nickel Alloys

It is used by following industries such as:

• Steel & Ferro Alloy Industries • Aluminium & Al Alloy Industries

• Copper & Copper Alloy Industries

• Nickel & Nickel Alloy Industries

• Atomic Energy

• Defence

• Metallurgy Laboratories

• Ceramic Industries

• Aeronautic Manufacturing Industries

• Mining Industries

• Refractory Metals (Ti, Zr)

• Ceramics

• Super Conductors

• Rare Earths

• UO2 / MOX

• Steels and Ferro Alloys

• Aluminium and Al Alloys

• Copper and Copper Alloys

• Nickel and Nickel Alloys

It is used by following industries such as:

• Steel & Ferro Alloy Industries • Aluminium & Al Alloy Industries

• Copper & Copper Alloy Industries

• Nickel & Nickel Alloy Industries

• Atomic Energy

• Defence

• Metallurgy Laboratories

• Ceramic Industries

• Aeronautic Manufacturing Industries

• Mining Industries